Why choose plastic as the raw material for car spoiler?

For high-speed cars, the rear spoiler installed at the rear edge of the trunk, which plays a very important role. In addition to bringing a beautiful decorative appearance to the car, more importantly, the spoiler can also effectively reduce the buoyancy of the car at high speeds, ensuring the stability of the car and helping to save fuel.

So do you know what the raw materials of car spoilers are usually?

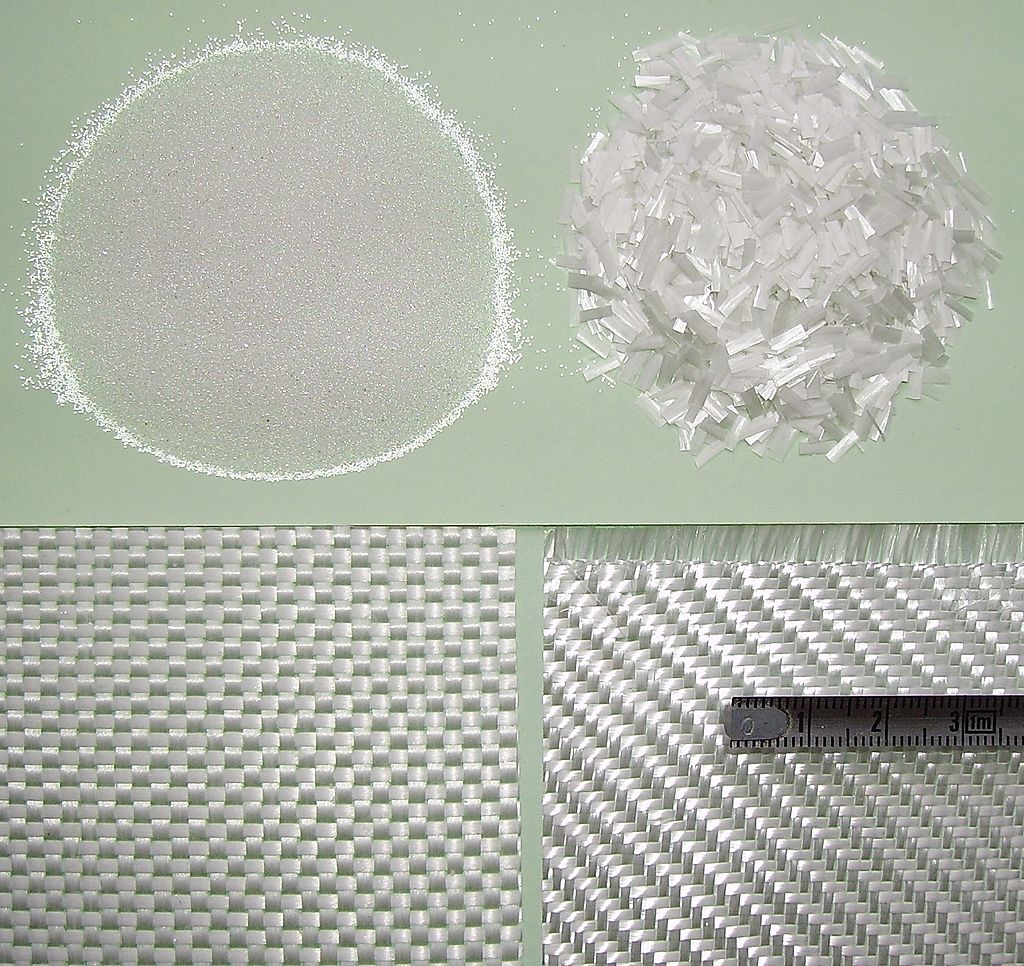

Usually, there are 4 types of materials that can be used to make car spoilers, including: fiberglass, aluminum alloy, carbon fiber and plastic. Each of these materials has advantages and disadvantages:

Fiberglass has high rigidity and low cost, but has poor environmental protection and has been gradually eliminated.

Aluminum alloy has good diversion effect but is heavy in weight.

Carbon fiber is rigid and lightweight, but expensive.

Plastic is lightweight, beautiful, has great freedom in design and is easy to process. It is currently the most widely used spoiler material. So this is also the car spoiler material that Haosheng chose.

At present, plastic spoilers can be formed using two processes, namely one-time blow molding and injection molding and welding. Among them, the blow molding process is more efficient, the mold cost is lower, and the amount of post-processing is small. Therefore, most plastic spoilers are currently produced using the blow molding method. The production process of the injection molding and welding method is to first injection mold the upper and lower pieces, and then weld the upper and lower pieces together. Although this method is faster in the injection molding stage, it often requires opening two injection molds, which is expensive. At the same time, subsequent ultrasonic welding or hot plate welding also requires the cooperation of the molds, so the cost is higher and the overall efficiency is lower. Low.

Our blow molds mainly use ABS plastic particles, which have the advantages of high melt strength, large elongation, and good balance between horizontal and vertical extensions. They can be widely used in large-scale industrial hollows for automobile spoilers, side steps, seats, etc. Molding needs for hollow blow molded products such as chairs and large pressure vessels.

Our injection molds mainly use PP plastic particles, which are easy to form, odorless and non-toxic, have the best heat resistance, have a high bending fatigue life, and more importantly, are low cost.

In conclusion, the rear spoiler of a high-speed car serves not only as a stylish addition but also as a crucial component for stability and fuel efficiency. While various materials can be used for manufacturing, plastic, particularly through blow molding or injection molding, emerges as the preferred choice due to its lightweight nature, design flexibility, and cost-effectiveness.